Eco printing with iron water

Hi Creative Mamas! If you love my natural dyeing tutorials you will absolutely love this article. I want to share with you how to do eco printing with iron water to create different effects on your natural color results.

In this post I will show you two different ways to apply iron water on your eco print which will work great for either paper or fabric. But first let’s clarify what iron water is and how we will use it in eco printing.

This post contains affiliate links, which means I receive a small commission, at no extra cost to you, if you make a purchase using this link. Please see my disclosure for more details.

Iron water in natural dyeing

I use iron water in natural dyeing as a color modifier. This is an optional step that can be done after you have naturally dyed your fabric or yarn.

For this step you can choose to make your own natural iron water solution which will allow you to create different shades and tones of the original color and its great for expanding the natural color palette.

You can turn yellow into green, yellow into grey, pink into maroon. The possibilities are abundant when you start experimenting with iron as a modifier.

The other option is to use ferrous sulphate powder and dilute it in the dye bath for more specific and less random results. I normally teach both methods in my live workshops.

Eco print

However, when it comes to eco printing I don’t use my homemade iron water because it’s very difficult to assess the amount of iron that I am applying to the fabric.

Please note that iron exposure can damage the natural fibers. This is a problem in eco printing because we will steam the fabric for 60 minutes and it’s a long time to expose the eco printed fabric to big amounts of iron.

You can use iron water as:

- mordant before printing

- dip for the plant material

- splatter before steaming

Plant material for eco printing

In eco printing we use flowers, leaves, rusty nails, copper wire as natural dyes. The idea is that we will extract the dye from the plant materials or we can use the mordant inherent to the copper and rust (if we use rusty nails for example) as a dye itself.

The easiest and most friendly way to do eco printing is to focus on plant materials as your natural dyes. I have prepared a list of the leaves and flowers which I recommend for eco printing both in paper and in fabric.

Download your Eco Printing leaves and flowers list

Eco printing paper with iron water

Make sure you read this step by step tutorial on eco printing paper, so that you the basic process of printing and know how to:

- make a bundle

- steam the bundle

- gather the materials needed for eco printing

Once you understand the process that its required to get a great natural print from leaves and flowers you can start playing around with iron water.

The following tutorial is based on my favorite method, which is mordanting the paper before printing.

This is a great strategy to create positive and negative prints. This is called Iron blanket and here is how you do it.

Iron blanket on paper

Make an iron water bath by diluting 1% of the weight of the paper of Ferrous sulfate. If my papers weighs 100 grams (3.5 oz) I only need 1gram (0.03 oz) of ferrous sulfate. You must dissolve well in hot water.

The iron blanket means that you will fully immerse a piece of paper in the iron bath and leave it for at least 1 minute. This piece of paper is your iron blanket.

For this tutorial I also decided to dip the leaves in the iron solution as well. This will make the prints a dark charcoal grey.

Remove the paper from the iron water and you will see the color changing to a light brown.

Place the leaves on top of the paper and place another piece of paper (which is only mordanted with alum) on top.

Make your bundle.

After steaming for 1 hour this will be the result.

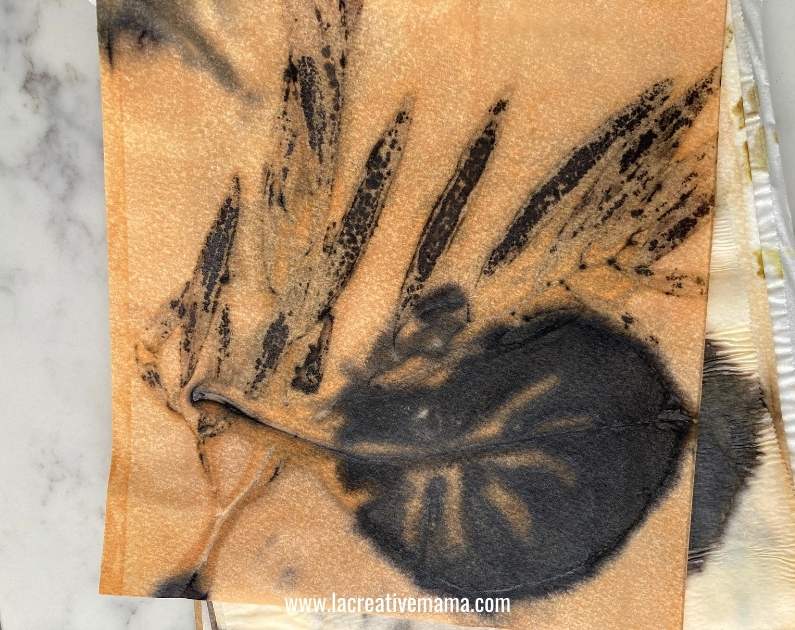

The photo below illustrates the bundle right after removing it from the steamer.

Here are the results from eco printing with the iron blanket on paper. The photo below is the print which was created by the alum mordanted paper which was on top of the iron blanket.

The paper has absorbed some of the iron color from the blanket and the leaves have reacted to the iron and created a dark almost a black print.

This is the print on the iron blanket paper. The paper has a brown color produced by the iron water and the leaves are very dark as well.

They are darker than in the other paper print because in this case the iron reacted twice.

These beautiful prints can also be transformed into eco printed gift wrapping as well as handmade notebooks.

Eco printing fabric with iron water

I now want to show you another way of printing using iron water with fabric. I have obtained many great results over the years by eco printing fabric using different types of flowers, leaves, rusty objects on several types of fabric such as linen, cotton, wool and silk.

In this tutorial I want to show you how I got a beautiful purple/blue result from printing a sunflower on a silk scarf using iron water.

You must be familiar with bundle dyeing so please read this tutorial and make sure that you are familiar with all the steps involved in making a fabric bundle for eco printing.

Sunflowers are not a great flowers to print with and I have never used them as a dye in natural dyeing before.

However, last week, I got a beautiful bunch of sunflowers as a gift, and since I am also crazy about re using and upcycling, I decided to have a go at using the flowers for printing before they dried.

So here is a little tutorial of how I did it 🙂 you will need a 100% silk scarf.

Prepare your iron bath following the same instructions as with paper.

Dip the sunflower and the leaves in the iron bath and place them randomly over one half of the silk scarf.

Fold the scarf over itself to create a top layer

Roll the scarf and make a little bundle. Steam for 1 hour.

After steaming for 1 hour, remove the bundle from the heat and leave it to dry by itself.

Once its dried, undo the bundle. Remove the leaves and flowers and rinse well.

The combination of the sunflower and the iron water created a purple/blue print. The leaves that didn’t have much iron in them gave a green print which is lovely as well.

Also it’s interesting to note that the iron water created a grey color for the entire scarf which makes a beautiful background color.

I love the result that I got and I am super happy to have discovered a way to make the most of my sunflowers!

I hope you have enjoyed this tutorial and please reach out should you have any questions!

Save this tutorial to your favorite Pinterest board

Hi Victoria, Thank you for your explanation with great photos. Would there be toxicity in handling the paper after using an iron powder in the process? When using fabric, the fabric can be washed after dyeing, but paper wouldn’t be washed, and I just wondered?

Thank you,

kind regards,

Jacqui

Hi Jacqui great question! If you are using iron powder at 1% of the paper weight I presume its ok, we never had a problem by doing this, however I caution people about allergies etc when handling iron since it can irritate the skin…

hi Victoria,

If I was to use an iron dip on cotton voile fabric after steam printing, using a logwood blanket, how much iron to darken everything slightly? The result was much paler than I wanted or expected.

How long should it be dipped, and should I dampen the fabric before dipping, and rinse it afterwards?